Quality Assurance

Pursuing the ultimate user experience

Give all-round quality assurance

100% Temperature drift detection

Full-process real-time temperature drift monitoring

Output real data report

Positioning Accuracy

Through multiple iterations of driver and motor sensor, FEELTEK provides a good positioning accuracy to guarantee the precision surface processing.

Drift Suppression

Through the optimization of driver and motor sensor, together with the amplifier, we make drift suppression controllable.

Acceleration performance & Overshoot control

The motor speed and acceleration performance is a guarantee for corner precision and overshoot, this is also the entry standard for precision processing (high speed filling, etching.etc)

Uniformity

Ensure the same speed and precision XY through.

Ensure the filling precision and micro-processing roundness.

Improve the parameter of angel filling and straight-line dither.

Z Axis calibration

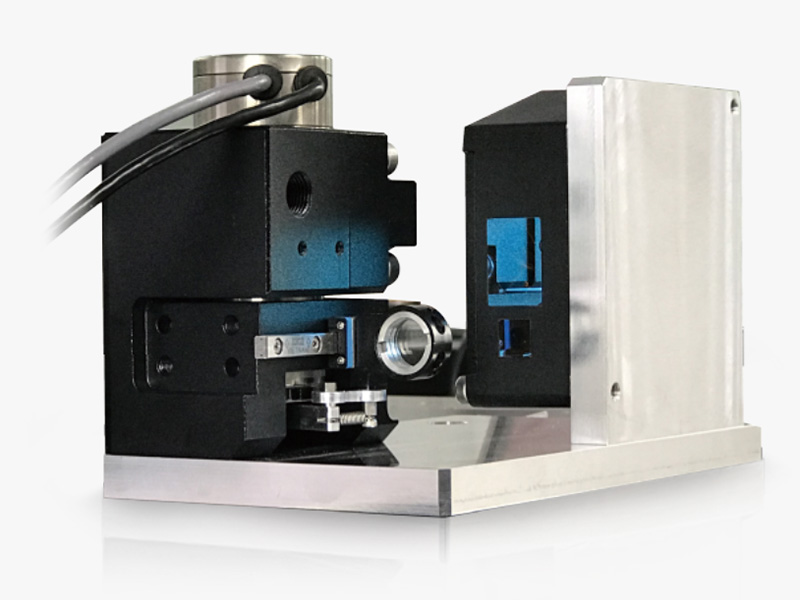

Through high precision position sensor calibration platform, FEELTEK make linearity, resolution and temperature drift data results of the dynamic axis can be visible. The quality is guaranteed.

Test report

● Calibration target: The position precision, temperature drift and linearity of Z axis.

● Calibration method: high precision range finder.

● Calibration tool: SICK (C30T05) .

● Calibration tool indicators: Range: 30mm, Precision: 0.3μm, Sampling interval: 12.5μs.

● Cal ibration

linearity: 99. 5%@3°

temperature drift: ≤4 μm@4hours

resolution: ≤1.2 μm