FEELTEK has been dedicating the 3D Dynamic Focus technology for more than 10 years.

We want to contribute this technology to industries and support industrial application upgrade.

About 3D Dynamic Focus System

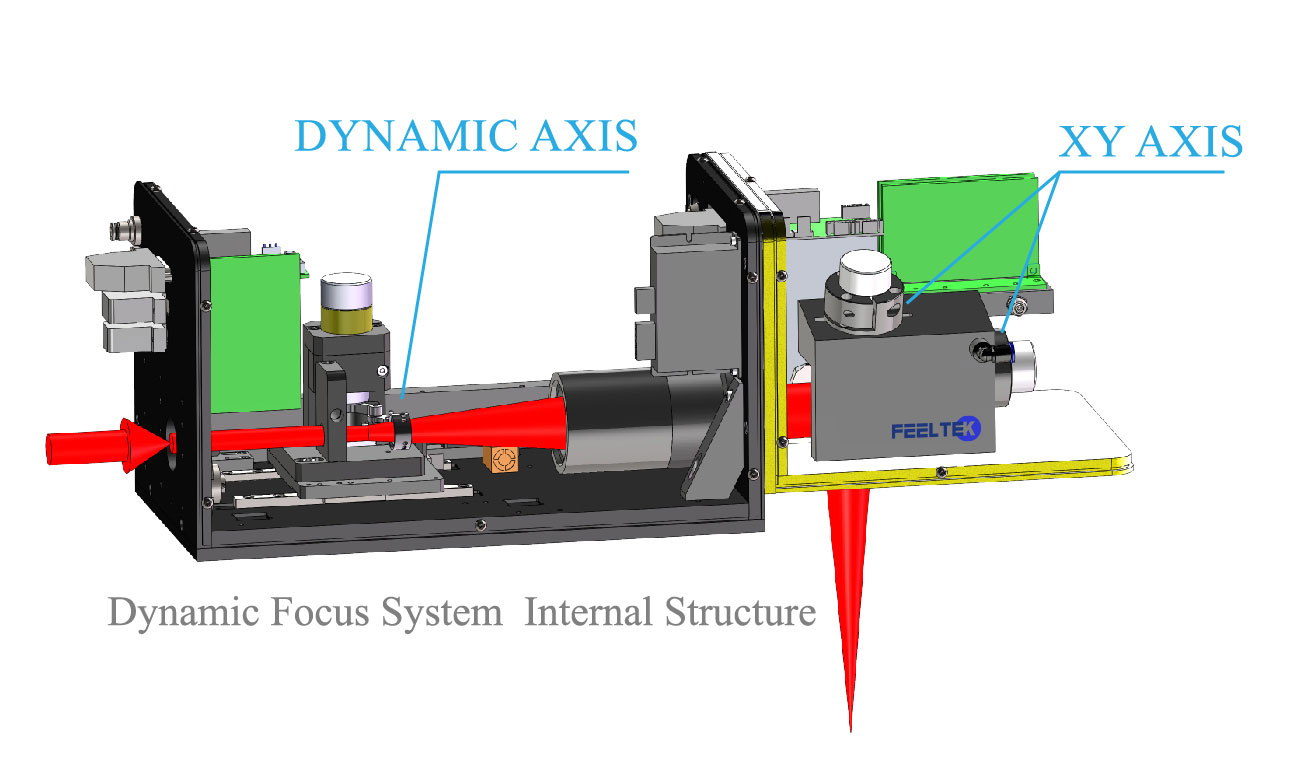

Generally, adding a third axis Z axis to a standard X Y axis forms a 3D dynamic focus system.

The working logical for 3D Dynamic Focus System is:

Through software control of the joint coordination of the Z axis and XY axis, with the different scanning position, the Z axis moves back and forward to compensate the focus, ensuring the spot uniformity and consistency in the whole working range.

Therefore, evaluating a marking effect, is not only depend on XY axis, but also related to repeatability, resolution, linearity, temperature drift.

Through high precision position sensor calibration platform, FEELTEK make linearity, resolution and temperature drift data results of the dynamic axis can be visible. The quality is guaranteed.

Meantime, the open design of dynamic axis helps in heat dissipation and avoid jam.

Difference between 2.5D and 3D dynamic focus system

2.5D Dynamic Focus system

is a End-focusing unit. It works with a f theta lens.

The working logical is:

The Z axis adjusts focal length of central point on working field, it minor adjusts in according to work depth's change, the f theta lens adjusts focal length of working field.

Generally, the aperture size of 2.5D system is within 20mm, working field is focus on small size. It is especially suitable for precision micro processing application such as deep engraving, drilling.

3D Dynamic Focus system

is a Pre-focusing unit.

The working logical is:

Through software control of the joint coordination of the Z axis and XY axis, with the different scanning position, the Z axis moves back and forward to compensate the focus, ensuring the spot uniformity and consistency in the whole working range.

When a 3D focus system processes flat and 3D surface working,, the movement of Z axis compensate the focus without f theta's limitation, so it has more options for aperture and work field, articulately suitable for super large laser processing.

2.5D Working diagram