Kowa ya san cewa aikin hakar mai yakan yi amfani da fasahar hakowa, da farko dai a fasa dutse da kayan aikin hakowa, a yi rami a cikin kasa, a tona wani rami mai zurfi, sannan a samu mai.

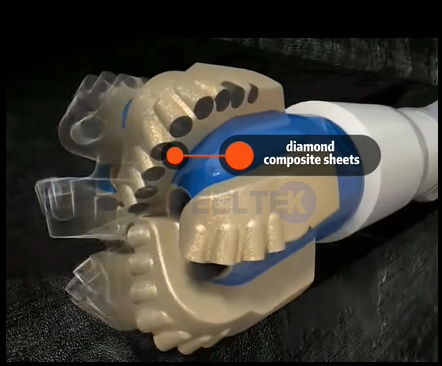

A matsayin babban karfi na hakowa, babban abin da ke cikin rawar sojan ya ƙunshi zanen lu'u-lu'u masu haɗaka, wanda aka sani da abu mafi wuya a yanayi.

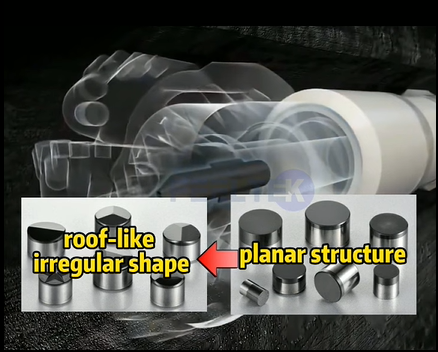

Har ila yau, don inganta iyawar hakowa da kuma dacewa da aikin hakowa, tsarin tsari na zane-zanen lu'u-lu'u na lu'u-lu'u a kan ma'auni yana buƙatar a samar da shi zuwa siffar da ba ta dace ba.

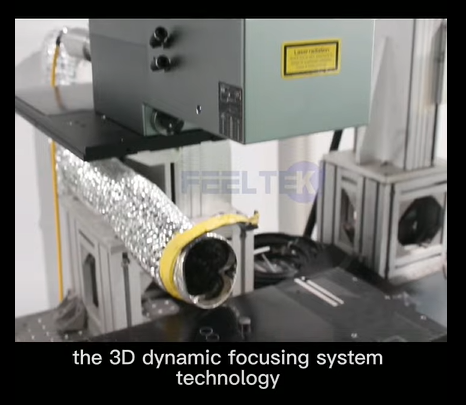

Yana da wuya ga ordinar 2D Laser scan shugaban don cimma wannan bukata.Duk da haka, da 3D tsauri mayar da hankali tsarin fasaha za a iya amfani da su daidaita mayar da hankali a cikin real lokaci a m surface a lokacin processing.Achieve daya-lokaci daidaici 3D subtractive masana'antu da yawa siffofi. kamar nika jirgin sama, waje da'ira, chamfering da sauransu.

Bugu da ƙari, ƙirar kayan aikin laser za a iya sanye take da tsarin sakawa a kan-axis ko kashe-axis.

Madaidaicin matsayi yayin aiki ana iya ƙara haɓakawa.

Lokacin aikawa: Agusta-26-2022