Ƙara rubutu, tambura, ko hotuna zuwa gilashin na iya zama ƙalubalen aikin Laser saboda ƙarancinsa. Koyaya, mun fahimci mahimmancin samun ingantattun tasirin zane-zane don keɓaɓɓun abubuwa.

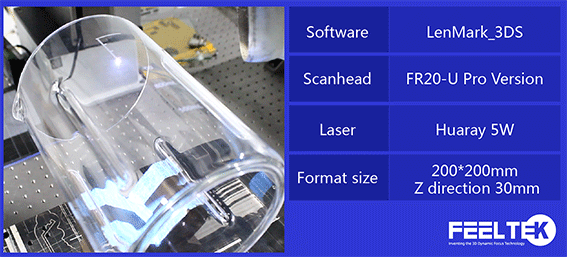

Bayan hulɗa tare da abokin ciniki, injiniyoyin FEELTEK sun ba da shawarar mafita mai yuwuwa wacce ta dace da buƙatun da ke sama:

Tasirin Tsari da Bincike:

1. A lokacin ainihin tsarin daidaitawa, zaɓin tsarin bai kamata ya zama babba ba.

2. Yi amfani da aikin tsinkaya yayin aiwatar da alama. Ayyukan tsinkaya zai canza girman zuwa wani matsayi, amma ingancin gani zai fi kyau.

3.Don tabbatar da kyakkyawan sakamako, gwada haɓaka ƙarfin laser zuwa kewayo tsakanin 5W-8W tunda ikon 3W bai isa ba a wasu lokuta.Wannan haɓakar wutar lantarki zai ba mu damar samun tasirin da ake so akan kewayon kayan gilashi. Bugu da ƙari, lokacin da ake buƙata don aiwatarwa zai bambanta bisa ƙayyadaddun ƙayyadaddun bayanai, tare da babban iko wanda zai haifar da ƙarshe da sauri.

4. Lokacin da 3D tsauri mai da hankali tsarin yi Z-direction gyara a kan lankwasa saman, an bada shawarar yin amfani da ƙarin yadudduka don tabbatar da sakamakon lankwasa surface marking.

5. Zaɓi madaidaicin adadin cika daidai gwargwadon ƙarfin laser na ainihi. Ana ba da shawarar cewa yawan cikawar kada ya zama mai yawa (kuma yana shafar inganci da tasirin bugu mara kyau)

Lokacin aikawa: Afrilu-15-2024