Waldawar Laser yana ɗaya daga cikin mahimman fasahar sarrafa kayan Laser tun shekarun 1970s.

Tare da ci gaba da balaga na fasaha da raguwar farashin na'urorin Laser, ƙirar walda ta Laser an fi amfani da su sosai a masana'antu daban-daban.

Masana'antu kamfanoni kamar HIGHYAG, TRUMPF sun sa kokarin cikin bincike da kuma ci gaban Laser Ana dubawa waldi fasaha da kayan aiki bisa ga tsari bukatun, da kuma cimma m Laser Ana dubawa waldi shuka mafita.

Idan aka kwatanta da fasahar walda ta gargajiya, an tabbatar da ingantaccen kuma ingantaccen fa'idodin walda na Laser.

A halin yanzu, masana'antun masana'antu suna ci gaba da haɓaka fasahar aikace-aikacen walda ta Laser, don haɓaka amfani da wannan tsari a cikin ƙarin masana'antu.

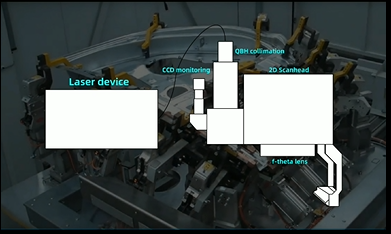

Tsarin walda na sikanin Laser na yau da kullun ya ƙunshi na'urori masu mahimmanci guda biyar: na'urar Laser, QBH collimation, CCD monitoring, scan head, da f-theta ruwan tabarau.

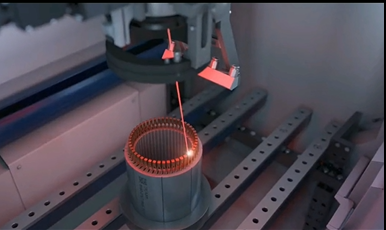

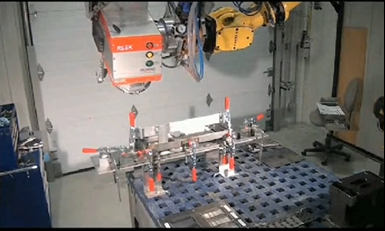

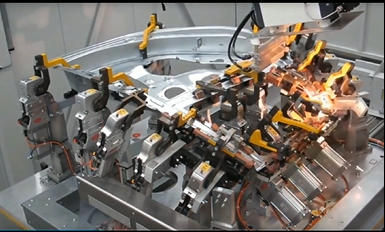

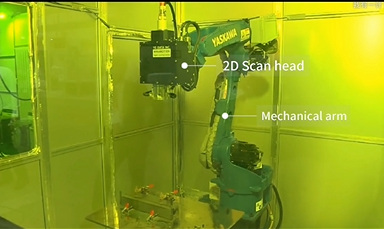

A farkon mataki, da Laser waldi bayani yafi amfani da wani 2D scan kai haɗe tare da inji hannu, ta yin amfani da m motsi na inji hannu da mahara digiri na 'yanci don gane duk batu waldi a cikin machining yankin a kafaffen mai da hankali tsawon. An yi amfani da wannan maganin a ko'ina a masana'antar kera motoci da kayan gyara don cimma nauyin nauyi na mota.

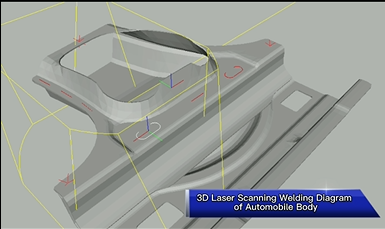

Tare da ci gaba da inganta aiki da kai, yin amfani da fasahar walƙiya ta Laser tana ƙara haɓakawa a cikin masana'antar. Misali, a cikin sabbin masana'antar abubuwan hawa makamashi da sauri, sabon ƙirar sassa na atomatik, batirin wutar lantarki, da sauran abubuwan sarrafawa, yana gabatarwa. babban kalubale ga data kasance bayani da kuma sanya gaba mafi girma bukatun ga fara-tasha mita da sakawa daidaito na inji hannu a waldi.

Yadda za a cimma high-gudun Laser waldi a kan wani babban hadaddun surface bangaren?Ta yaya cimma sauri mai da hankali tsawon daidaita a karkashin daban-daban aiki Heights? Duk wadannan sun zama wuya waldi tsari hažaka.

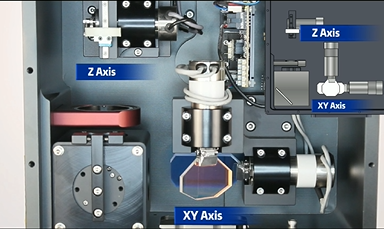

Za mu iya hažaka da 2D scan shugaban a cikin Laser Ana dubawa waldi tsarin kayan aiki zuwa 3D tsauri mayar da hankali tsarin, da Z-direction tsauri axis na tsauri mayar da hankali tsarin iya aiki tare a tare da XY axis. Kamar yadda aiki nesa canje-canje a lokacin waldi tsari, da Z-direction tsauri axis motsa baya da kuma gaba don yin mayar da hankali diyya, zai iya tabbatar da daidaito na tabo mayar da hankali a cikin dukan aiki tsari, da kuma gane high-gudun hadedde waldi na da manyan kewayon hadaddun surface sassa, da kuma ƙwarai rage robotic hannu ta sakawa lokaci da mataki lokaci a samar.

A lokaci guda, don rage kuskuren sakawa da ya haifar da yawan farawa da dakatarwar hannun injin, saurin daidaitawar mayar da hankali na tsayi daban-daban za a iya gane ta hanyar cikakkiyar daidaituwa tsakanin madaidaicin madaidaicin Z-direction da XY axis na tsauri. mayar da hankali tsarin, da kuma gama waldi work.The yadda ya dace ya sosai inganta, sauki cimma samar line aiki da kai.

Sanin karin bayani daga tashar FEELTEK TECHNOLOGY

Lokacin aikawa: Satumba-23-2022