Low MOQ for Small Metal Plaque Engraving - 3D Scanner-Fiber-F20 – FEELTEK

Low MOQ for Small Metal Plaque Engraving - 3D Scanner-Fiber-F20 – FEELTEK Detail:

Product characteristics

Description

- Standard XY2-100 protocol, open interface, compatible with popular control card on the market.

- Support wavelength: 1064nm.

- Designed based on output beam characteristics of popular laser on the market, maximize the use of optical lens.

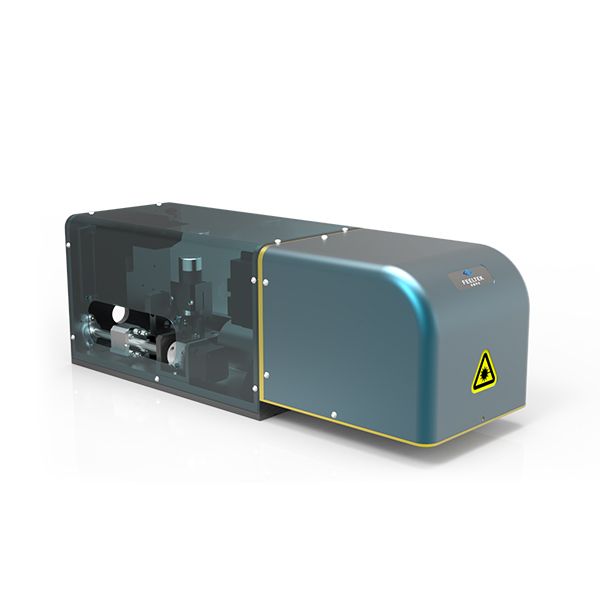

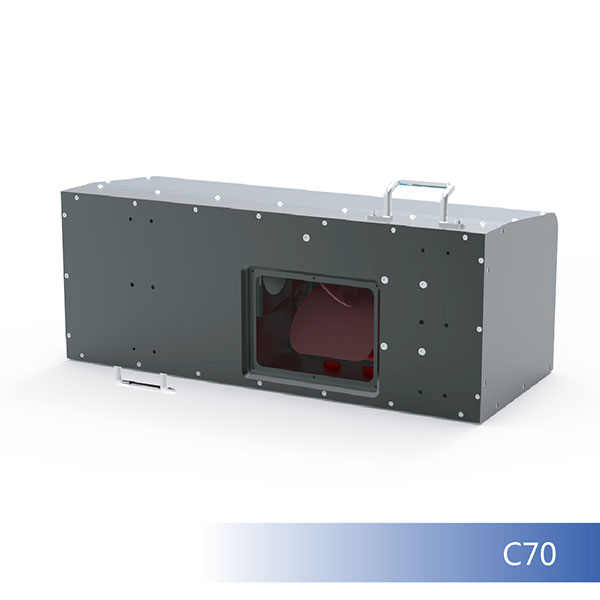

- CNC shell, dust prevention, compact structure, easy to integrate.

- Optional water-cooling design can be applied to the strict temperature drift occasions.

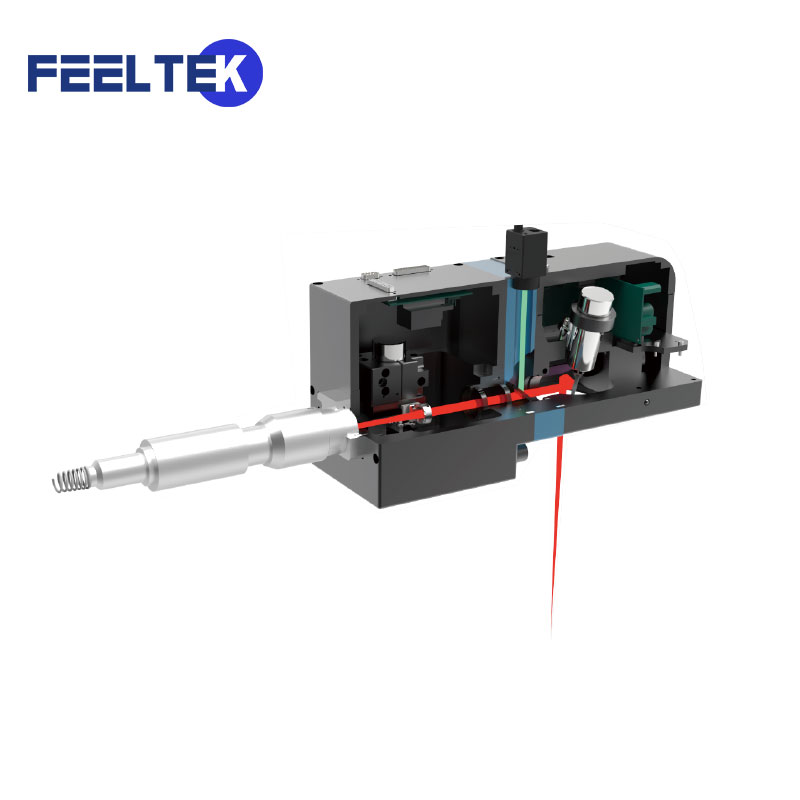

- Double driving Z axis dynamic focus module design,response frequency≥100HZ@±10°, easy to achieve Z depth150mm@300mmx300mm, applied to the platform,3D surface high-speed processing.

- It can be used in kinds of the moving line, visual positioning, deep-carving, step marking and other production line applications with LenMark and WinMark software.

- Support high power components customization, max. power up to 4KW.

- The P2 version adopts the digital pulse width modulation driving technology, owns higher response speed and lower temperature drift.

Application

Large filed marking,Engraving,Welding,Scribing,Texture,Surface removing,Surface Treatment,Additive Manufacturing

Version

Pro,P2

General specification

|

Power Supply |

InputVoltage(VAC) |

170-264 |

|

OutputVoltage(VDC) |

±24/±15 |

|

|

Current(A) |

5A(2sets) |

Control Card

|

Output Interface |

XY2-100 Protocal |

|

Input Interface |

Data Communication Interface |

|

Laser Type |

Fiber |

Environmental Requirement

|

Ambienttemperature(°) |

0~±50 |

|

Storagetemperature(°) |

-10~±60 |

|

Humidity |

≤75% non condensing |

Galvanometer Specifications

|

Version |

Pro |

P2 |

|

Scan Angle(°) |

±11.25 |

±11 |

|

Repeatability(urad) |

8 |

5 |

|

Max. Gain Drift(ppm/K) |

100 |

50 |

|

Max.Offset Drift(urad/) |

30 |

15 |

|

Long-term drift over 8h(mrad) |

0.5 |

0.1 |

|

Max.processing speed(characters/s) |

350@200×200 |

|

|

Tracking Error(ms) |

≤0.28 |

≤0.27 |

Working filed & Spot Diameter

|

Working Field(mm) |

100×100×40 |

200×200×150 |

300×300×200 |

|

Focal length(mm) |

120 |

240 |

360 |

|

The Min.Spot Diameter@1/e²(mm) |

0.0156 |

0.0257 |

0.0362 |

|

Working Field(mm) |

400×400×200 |

500×500×200 |

600×600×200 |

|

Focal length(mm) |

480 |

600 |

720 |

|

The Min.Spot Diameter@1/e²(mm) |

0.0462 |

0.0565 |

0.0661 |

Product detail pictures:

Related Product Guide:

We now have a highly efficient crew to deal with inquiries from clients. Our intention is "100% shopper pleasure by our merchandise quality, price tag & our staff service" and take pleasure in a very good standing amongst purchasers. With quite a few factories, we can easily provide a wide vary of Low MOQ for Small Metal Plaque Engraving - 3D Scanner-Fiber-F20 – FEELTEK , The product will supply to all over the world, such as: Ukraine , Boston , Romania , Our organization. Situated inside the national civilized cities, the visitors is very easy, unique geographical and economic situations. We pursue a "people-oriented, meticulous manufacturing, brainstorm, construct brilliant" organization. hilosophy. Strict top quality management, fantastic service, reasonable cost in Myanmar is our stand on the premise of competition. If vital, welcome to make contact with us by our web page or telephone consultation, we've been likely to be pleased to serve you.

The supplier cooperation attitude is very good, encountered various problems, always willing to cooperate with us, to us as the real God.