Everyone knows that oil exploration often uses drilling technology,firstly break the rock with the drilling tool, drill into the ground, drill a hole of a certain depth, and obtain oil.

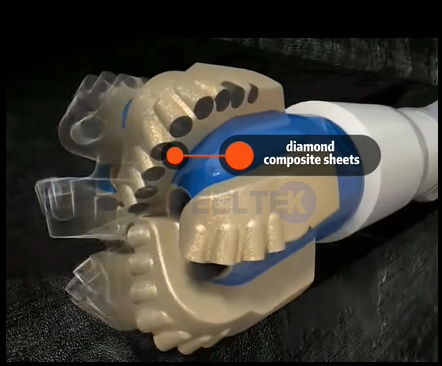

As the main force of drilling, the core component of the drill bit is composed of diamond composite sheets, which is known as the hardest substance in nature.

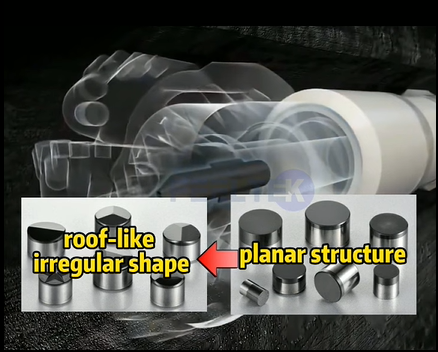

At the same time, in order to improve the drilling capacity and efficiency of the drill bit, the planar structure of the diamond composite sheet on the drill bit needs to be produced into a roof-like irregular shape.

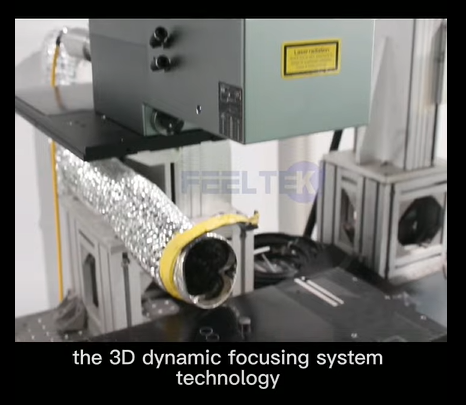

It is difficult for ordinar 2D laser scan head to achieve this requirement.However,the 3D dynamic focusing system technology can be used to adjust the focus in real time at the irregular surface during processing.Achieve one-time precision 3D subtractive manufacturing of many shapes such as grinding plane, outer circle, chamfering and so on.

In addition, the laser equipment design can be equipped with on-axis or off-axis positioning system.

The precise positioning during processing can be further improved.

Post time: Aug-26-2022