With the deep involvement of laser scan head processing technology in the advanced industry, the increasing integrators start to pay attention to the position deviation of the processing effect caused by temperature change.

Dimensional errors that occur with temperature change, we call it temperature drift.

Some high-end scan head manufacturers begin to take the temperature drift as a quality standard and include it in the production quality system, thus ensuring the objectivity of temperature drift.

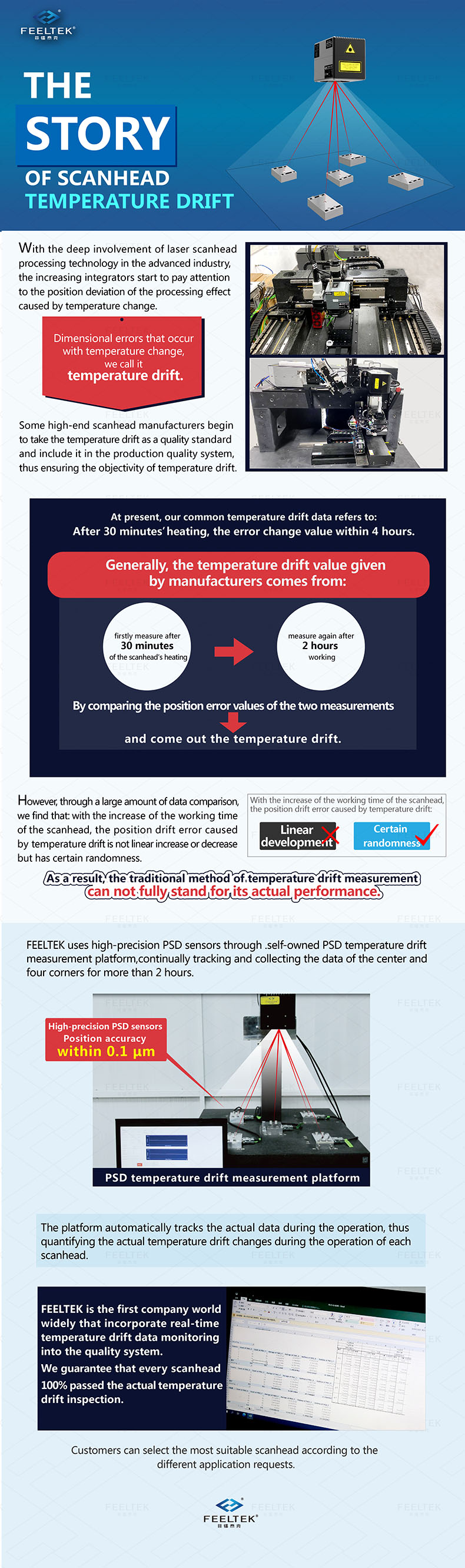

At present, our common temperature drift data refers to: after 30 minutes’ heater, the error change value within 4 hours.

Generally, the temperature drift value given by manufacturers comes from: firstly measure after 30 minutes of the scan head’s heater, measure again after 2 hours working.

By comparing the position error values of the two measurements, and come out the temperature drift.

However, through a large amount of data comparison, we find that: with the increase of the working time of the scan head, the position drift error caused by temperature drift is not linear increase or decrease but has certain randomness.

As a result, the traditional method of temperature drift measurement can not fully stand for its actual performance.

FEELTEK uses high-precision PSD sensors through a self-owned PSD temperature drift measurement platform, continually tracking and collecting the data of the center and four corners for more than 2 hours.

The platform automatically tracks the actual data during the operation, thus quantifying the actual temperature drift changes during the operation of each scan head.

FEELTEK is the first company world widely that incorporate real-time temperature drift data monitoring into the quality system. We guarantee that every scan head 100% passed the actual temperature drift inspection.

Customers can select the most suitable scan head according to the different application requests.

Post time: Oct-31-2021