Have you ever noticed the headlights displayed on cars at night? At night when the outline of the car cannot be clearly seen, the headlights are the best advertisement for car manufacturers.

n an era of increasing pursuit of personalization, the interior and exterior decorations of automobiles are characterized by irregular and special-shaped curved surfaces. So how to ensure the uniformity of the light spot at each point?

The specific requirements for this process are as follows:

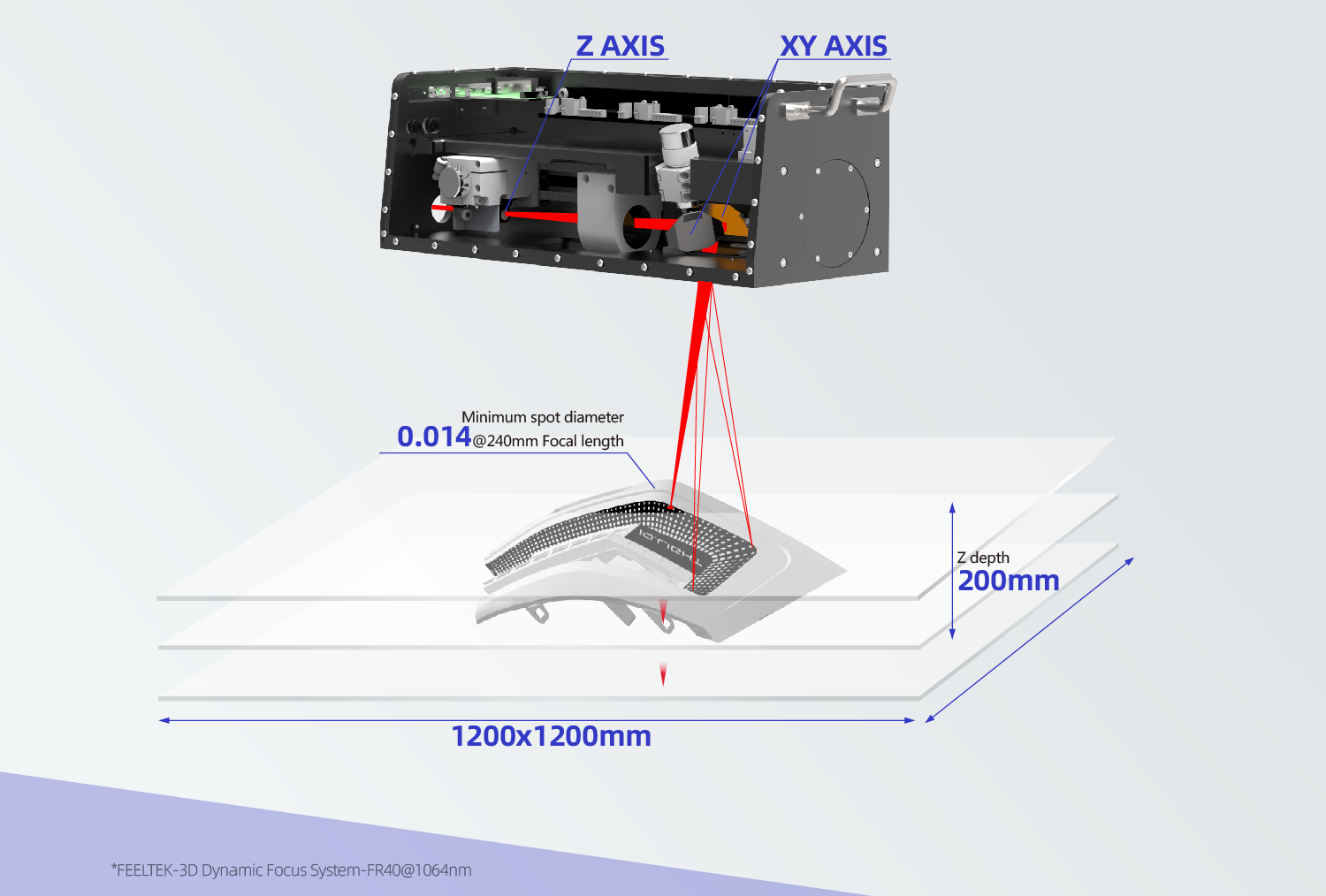

-Achieve one-step engraving of large-size curved surfaces (1200*50mm) of automotive parts.

- Maintains substrate integrity without causing substrate damage.

- Ensure uniform light transmission performance.

After consultation with the customer, FEELTEL technician proposed a feasible solution that meets the above requirements:

- Laser source: 200W MOPA

- Dynamic focus system: FR20-F

- Software function: LenMark_3DS, specifically for surface engraving

FEELTEK’s dynamic focusing technology ensures spot uniformity through: The Z-direction dynamic axis and the XY axis are jointly coordinated. With the different scanning positions, the Z-direction dynamic axis moves forward and backward for focus compensation, and the processing format is no longer affected by the field lens. Limitation, a wider range of processing can be achieved.

Welcome to discuss with us the processing applications of automotive interior and exterior decorations.

Post time: Mar-05-2024