Laser welding ke e 'ngoe ea mahlale a bohlokoa a ho lokisa thepa ea laser ho tloha ka bo-1970.

Ka kholo e tsoelang pele ea thekenoloji le ho theoha ha theko ea lisebelisoa tsa laser, merero ea li-welding ea laser e sebelisitsoe haholo indastering e fapaneng.

Likhamphani tsa liindasteri tse kang HIGHYAG,TRUMPF li kentse boiteko ba ho etsa lipatlisiso le nts'etsopele ea theknoloji ea welding ea laser scanning le lisebelisoa ho latela litlhoko tsa ts'ebetso, 'me li fihletse litharollo tse sebetsang tsa semela sa laser scanning.

Ha ho bapisoa le theknoloji ea khale ea ho tjheseletsa, melemo e nepahetseng haholoanyane le e sebetsang haholoanyane ea laser scanning welding e netefalitsoe ka botlalo.

Ho sa le joalo, litsebi tsa indasteri li ntse li tsoela pele ho ntlafatsa theknoloji ea kopo ea laser welding, ho khothaletsa tšebeliso ea ts'ebetso ena liindastering tse ngata.

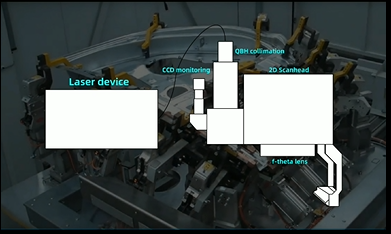

Sehlopha se tloaelehileng sa lisebelisoa tsa laser scanning welding se na le li-module tse hlano tsa mantlha: sesebelisoa sa laser, QBH collimation, CCD monitoring, scan head, le f-theta lens.

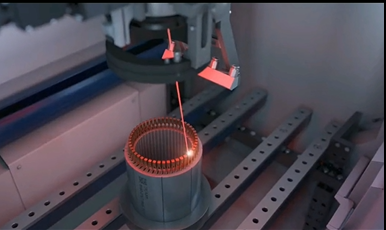

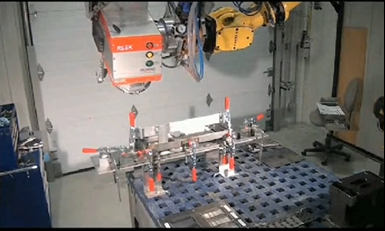

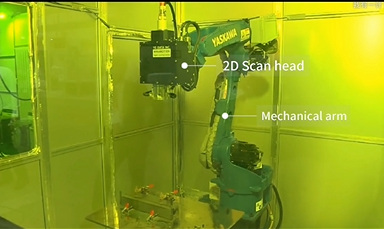

Mothating oa pele, tharollo ea welding ea laser haholo-holo e ne e sebelisa hlooho ea 2D scan e kopantsoeng le letsoho la mochini, ho sebelisa motsamao o feto-fetohang oa letsoho la mochini le nang le likhato tse ngata tsa tokoloho ho hlokomela lintlha tsohle tsa ho tjheseletsa sebakeng sa machining ka bolelele bo tsitsitseng. Tharollo ena e sebelisitsoe haholo tlhahisong e kholo ea 'mele ea likoloi le likarolo tse ling ho fihlela mabone a koloi.

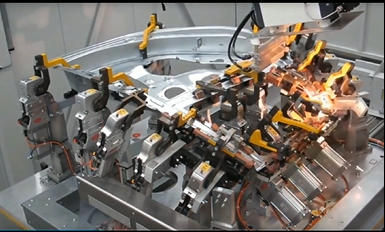

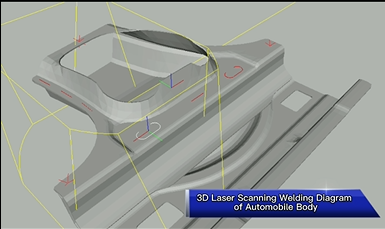

Ka ntlafatso e tsoelang pele ea othomathike, ts'ebeliso ea theknoloji ea laser scanning welding e atolosoa indastering. Mohlala, indastering e ntseng e hola ka potlako ea makoloi a macha, moralo o mocha oa likarolo tsa likoloi, libeteri tsa motlakase, le lisebelisoa tse ling, lia hlahisa. phephetso e kholo ho tharollo e teng 'me e beha litlhoko tse phahameng bakeng sa maqhubu a ho qala-ho emisa le ho nepahala ha boemo ba letsoho la mochine ka ho tjheseletsa.

Joang ho fihlela lebelo le phahameng la laser welding holim'a karolo e kholo e rarahaneng ea holim'a metsi?U ka finyella bolelele bo potlakileng ba ho tsepamisa maikutlo joang tlas'a libaka tse fapaneng tsa mosebetsi?

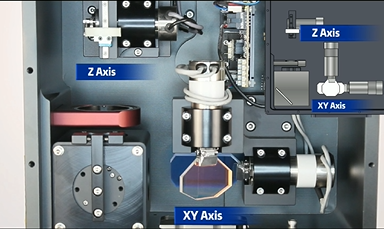

Re ka ntlafatsa hlooho ea 2D scanning mochining oa laser scanning welding system ho ea ho 3D dynamic focus axis ea Z-direction dynamic axis ea dynamic focus system e ka sebelisana 'moho le XY axis. Ha sebaka sa ho sebetsa se ntse se fetoha nakong ea ts'ebetso ea welding, axis e matla ea Z-direction e ntse e ea pele le morao ho etsa puseletso e tsepamisitsoeng maikutlo, e ka netefatsa ho ts'oana ha sepheo sa ts'ebetso eohle ea ts'ebetso, le ho hlokomela ts'ebetso ea tjheseletso e phahameng ka lebelo le holimo. mefuta e mengata ea likarolo tse rarahaneng tsa holim'a metsi, 'me e fokotsa haholo nako ea ho beha letsoho la robotiki le nako ea mohato oa tlhahiso.

Ka nako e ts'oanang, ho fokotsa phoso ea boemo bo bakoang ke ho qala le ho emisa khafetsa ha letsoho la mochini, phetoho e potlakileng ea ho tsepamisa maikutlo ea bophahamo bo fapaneng e ka bonoa ka khokahano e felletseng lipakeng tsa Z-direction dynamic axis le XY axis ea dynamic. mokhoa oa ho tsepamisa maikutlo, 'me u qete mosebetsi oa ho tjheseletsa.Ho sebetsa hantle ho ntlafalitse haholo, ho le bonolo ho fihlella tlhahiso ea line automation.

Tseba haholoanyane ho tsoa ho mocha oa FEELTEK TECHNOLOGY

Nako ea poso: Sep-23-2022