Top Suppliers Large Scale Metal 3d Printing - Software – FEELTEK

Top Suppliers Large Scale Metal 3d Printing - Software – FEELTEK Detail:

Product characteristics

Large field marking,3D surface marking, engraving,3D printing.Support customized development

- Support the import of kinds of vector files and bitmap files.

- Support network port, serial port data reading, can facilitate automatic production line data interfaction.

- Self-developed software, support further development. Optimization for application, open interface, can be customized to requirements.

- Support multi correction methods: fast and high precision correction on high precision ideal platform and free adjustment of each position focal point under the non-ideal plane, and finally achieve full format focus consistency.

- Provide production line marking, visual positioning marking, automation marking, and other solutions to meet the diverse needs of the customer.

- Support 3D application, support importing of STL model,self-developed model, etc. Support 3D data editing rapid realization of 3D surface marking, relief processing.

- Support expansion of 3D scanning requirement, it can realize the rapid localization and reverse processing of 3D workpieces, and the rapid marking of workpieces can be realized without the workpiece model.

Standard configuration:

Large field marking

Optional configuration:

Platform moving line, 3D surface moving line, CCD, Projection Positioning,3D surface marking, Relief, 360°rotation marking,

CCD positioning reading

The visual module of LenMark software is used for target workpiece detection, graphic positioning, marking effect reading and other production line application scenes, which provides more possibilities for laser processing automation and automatic detection.

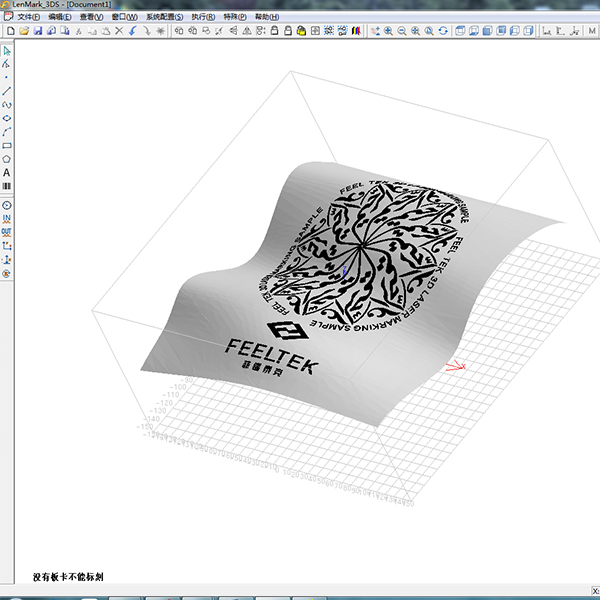

3D surface map undeformed

LenMark software supports self-built 3D model libraries and imported stl3D model files.

The 3D curly bread coating technology developed by FEELTEK can effectively avoid the distortion in 3D map and realize the perfect 3D map.

3D projection allows users to easily map, mark, and read the surface two-dimension code.

Dual-scan head marking

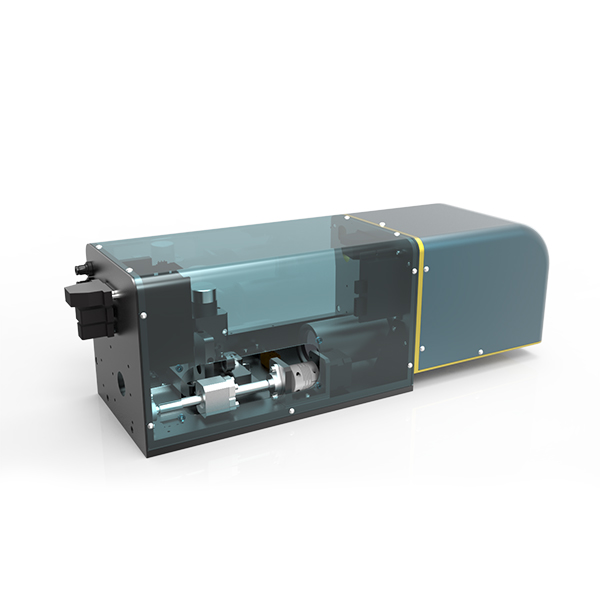

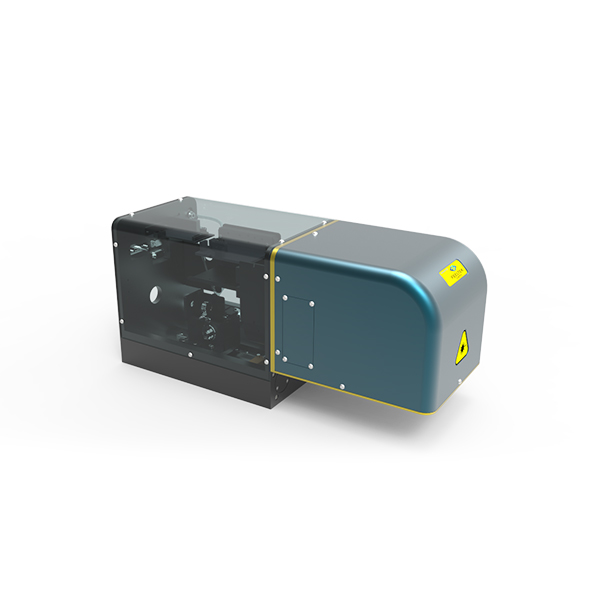

The unique FEELTEK dual dynamic focus system, independently distributes the light source and processing parameters of the two systems through one set of software control. The motion coordinates of the two systems coincide completely in the processing space.It can be used in the application scenarios of laser heat treatment, additive manufacturing which require different light sources to act on the workpiece in order to meet the requirements of processing technology and efficiency.

The customizable system API interface

LenMark provides a rich API interface for supporting the user to realize the secondary development, including the control card API and the software API, which can meet the needs of the users from the development of hardware-based control to the application-level-based process development.

Path optimization for real-time previewing

By implementing the preview function, users can adjust the order of marking the path to meet the needs of industrial field efficiency and process to the greatest extent.

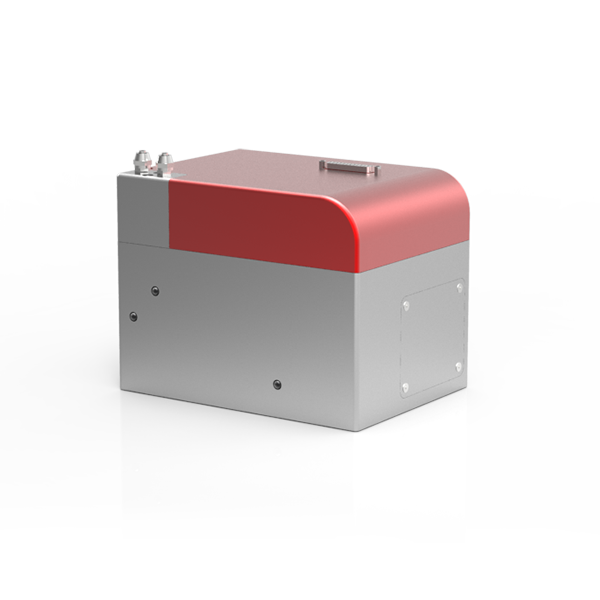

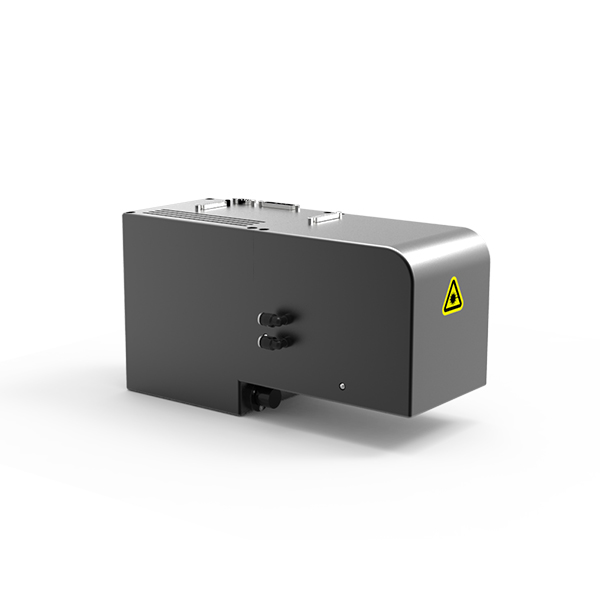

Product detail pictures:

Related Product Guide:

Our enterprise insists all along the standard policy of "product high-quality is base of business survival; client satisfaction could be the staring point and ending of an business; persistent improvement is eternal pursuit of staff" as well as consistent purpose of "reputation first, client first" for Top Suppliers Large Scale Metal 3d Printing - Software – FEELTEK , The product will supply to all over the world, such as: South Africa , Iran , Bahamas , We seriously promise that we provide all the customers with the best quality products, the most competitive prices and the most prompt delivery. We hope to win a resplendent future for customers and ourselves.

Hope that the company could stick to the enterprise spirit of "Quality, Efficiency, Innovation and Integrity", it will be better and better in the future.