I-laser welding ingenye yobuchwepheshe obubalulekile bokucubungula izinto ze-laser kusukela ngawo-1970.

Ngokukhula okuqhubekayo kobuchwepheshe kanye nokwehla kwentengo yemishini ye-laser, izikimu zokushisela i-laser zisetshenziswe kabanzi ezimbonini ezahlukahlukene.

Izinkampani zezimboni ezifana ne-HIGHYAG,TRUMPF zenze imizamo ocwaningweni nasekuthuthukisweni kobuchwepheshe bokushisela ukuskena kwe-laser kanye nemishini ngokuya ngezidingo zenqubo, futhi zithole izixazululo ezisebenzayo zezitshalo zokushisela i-laser.

Uma kuqhathaniswa nobuchwepheshe bendabuko bokushisela, izinzuzo ezinembe kakhudlwana nezisebenza kahle kakhulu zokushisela i-laser ziqinisekiswe ngokugcwele.

Okwamanje, ochwepheshe bezimboni bayaqhubeka nokuthuthukisa ubuchwepheshe besicelo se-laser welding, ukukhuthaza ukusetshenziswa kwale nqubo ezimbonini eziningi.

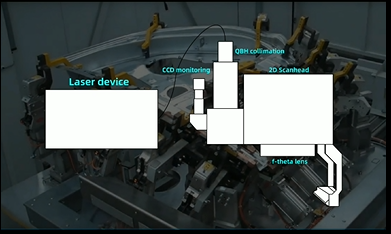

Isethi evamile yezinhlelo zokushisela zokuskena nge-laser iqukethe amamojula amahlanu ayinhloko: idivayisi ye-laser, ukushayisana kwe-QBH, ukuqapha kwe-CCD, ikhanda lokuskena, ne-f-theta lens.

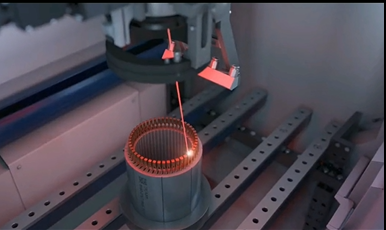

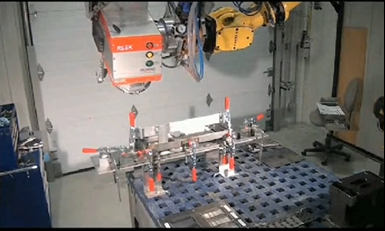

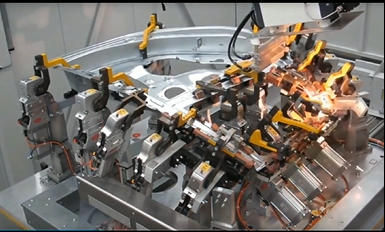

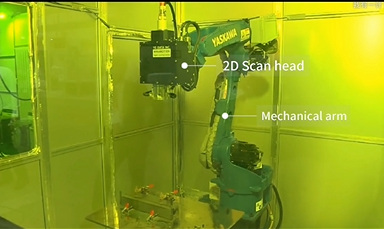

Esikhathini sokuqala, isisombululo se-laser welding ngokuyinhloko sasisebenzisa ikhanda lokuskena le-2D elihlanganiswe nengalo ewumshini, kusetshenziswa ukunyakaza okuguquguqukayo kwengalo ewumshini enamazinga amaningi enkululeko ukuze kubonakale wonke amaphoyinti wokushisela endaweni yomshini ngobude obugxilile obugxilile. Lesi sixazululo sisetshenziswe kabanzi ekwenziweni ngobuningi kwemizimba yezimoto nezingxenye eziyisipele ukuze kuzuzwe ukukhanya kwezimoto.

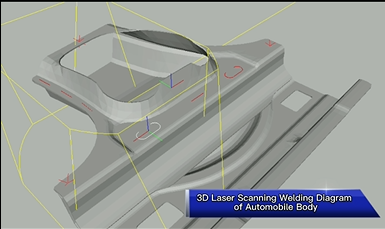

Ngokuthuthuka okuqhubekayo kokuzenzakalela, ukusetshenziswa kobuchwepheshe bokushisela i-laser kunwebeka kakhulu embonini.Ngokwesibonelo, embonini yezimoto zamandla amasha ekhula ngokushesha, umklamo omusha wezingxenye zezimoto, amabhethri kagesi, nezinye izingxenye ezicutshungulwayo, kuyaveza. inselele enkulu kusixazululo esikhona futhi ibeka phambili izidingo eziphakeme zefrikhwensi yokumisa kanye nokunemba kokumisa ingalo ewumshini ekushiseleni.

Ungafinyelela kanjani ukushisela nge-laser enesivinini esikhulu endaweni enkulu eyinkimbinkimbi?Ubufinyelela kanjani ubude be-focal esheshayo ukulungisa ngaphansi kobude obuhlukahlukene bomsebenzi?Konke lokhu kube nzima ukuthuthukiswa kwenqubo yokushisela.

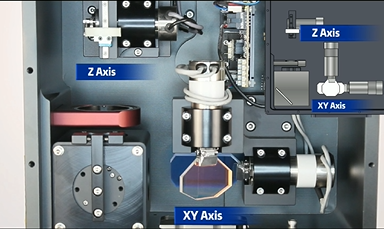

Singakwazi ukuthuthukisa ikhanda lokuskena le-2D kumishini yesistimu yokushisela i-laser ibe uhlelo lokugxila oluguqukayo lwe-3D, i-axis eguquguqukayo ye-Z-direction yesistimu yokugxila eguquguqukayo ingabambisana ngokuhlangana ne-XY axis. Njengoba ibanga lokusebenza lishintsha phakathi nenqubo yokushisela, i-eksisi eguquguqukayo ye-Z-direction iya emuva naphambili ukwenza isinxephezelo sokugxila, ingaqinisekisa ukuvumelana kokugxila kwendawo kuyo yonke inqubo yokusebenza, futhi ibone ukushisela okudidiyelwe kwesivinini esikhulu. uhla olukhulu lwezingxenye zomhlaba eziyinkimbinkimbi, futhi kunciphisa kakhulu isikhathi sokuma kwengalo yerobhothi kanye nesinyathelo sokukhiqiza.

Ngasikhathi sinye, ukuze kuncishiswe iphutha lokuma elibangelwa ukuqala njalo nokuma kwengalo engumshini, ukulungiswa okusheshayo kokugxila kokuphakama okuhlukene kungenziwa ngokusebenzisana okuphelele phakathi kwe-axis eguquguqukayo ye-Z-direction kanye ne-XY axis ye-dynamic. isistimu yokugxila, futhi uqedele umsebenzi wokushisela.Ukusebenza kahle kuye kwaba ngcono kakhulu, kulula ukufeza umugqa wokukhiqiza ozenzakalelayo.

Yazi okwengeziwe esiteshini i-FEELTEK TECHNOLOGY

Isikhathi sokuthumela: Sep-23-2022